Wonderful Info About What Is 60/40 Solder Used For

Decoding 60/40 Solder

1. Understanding the Basics

Ever wondered what keeps all those wires and electronic components happily connected inside your gadgets? Chances are, it's solder. But not just any solder. We're diving deep into the world of 60/40 solder today. It's like the all-purpose flour of the electronics world — incredibly versatile and widely used.

So, what exactly is 60/40 solder? Simply put, it's an alloy (a mixture of metals) made up of 60% tin and 40% lead. These two metals come together to create something special with a relatively low melting point, which is crucial for safely joining delicate electronic parts.

Why tin and lead? Well, tin is known for its excellent wetting properties. "Wetting," in soldering terms, means how well the molten solder flows and adheres to the metal surfaces you're trying to join. Lead, on the other hand, helps to lower the melting point and improve the solder's mechanical properties, making it less brittle.

Think of it like this: tin is the enthusiastic hugger, making sure everything gets a good grip, and lead is the smooth talker, making sure the process is easy and doesn't damage anything in the process. Together, they form a near-perfect team for a variety of electronic projects. Now, let's talk about where you'd actually use this stuff.

YI LIN 60/40 Solder 100g Tin Lead Rosin Core Wire For Electrical

Where Does 60/40 Solder Shine? A World of Applications

2. Electronics Assembly and Repair

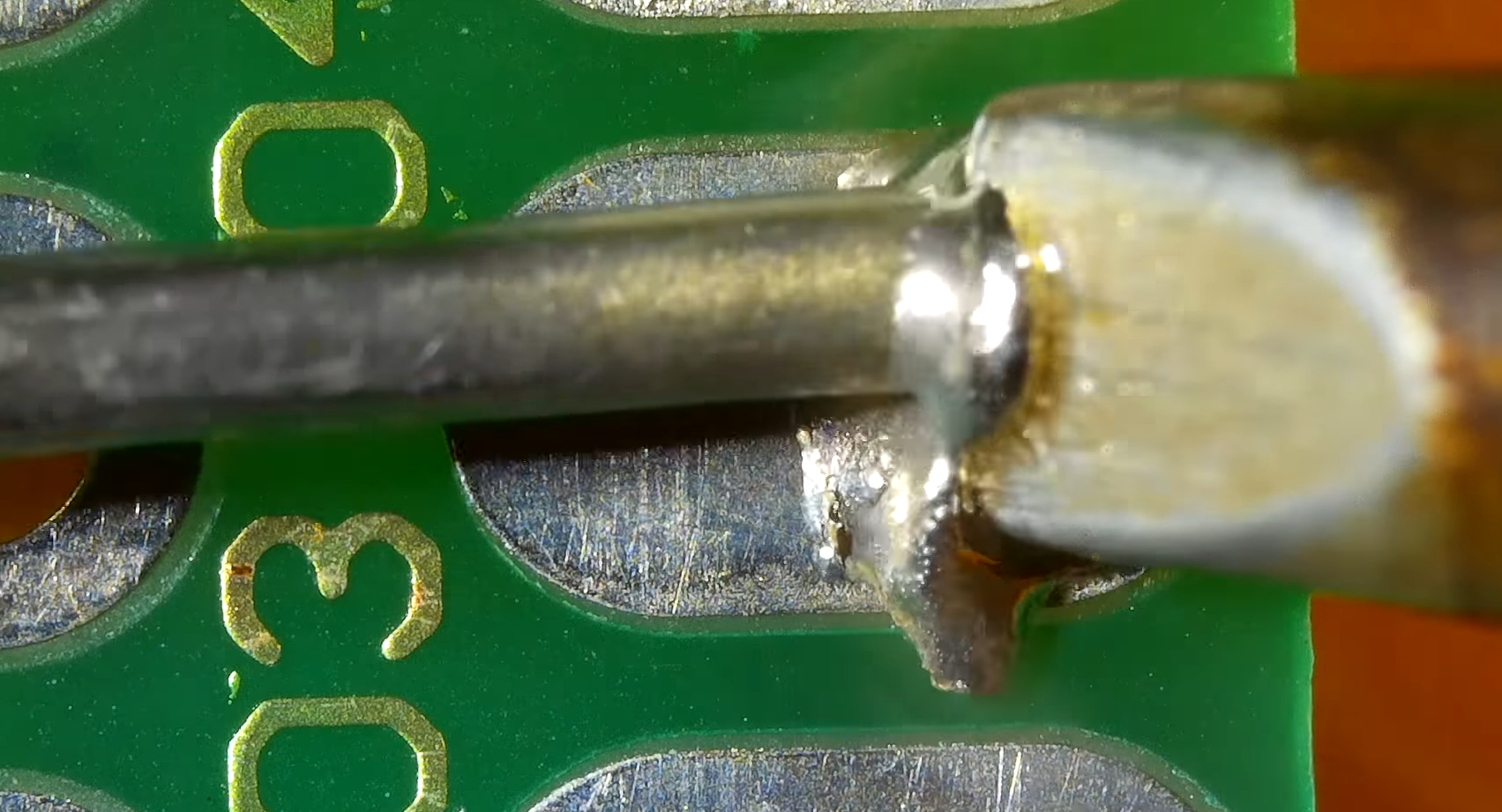

This is where 60/40 solder truly excels. From assembling circuit boards to repairing old radios, its relatively low melting point makes it ideal for working with heat-sensitive components. You don't want to accidentally fry your precious transistors, after all! Imagine trying to fix a vintage guitar amp only to melt a crucial resistor — nightmare fuel for any electronics enthusiast.

The ease of use is another huge plus. Whether you're a seasoned engineer or just starting out with electronics, 60/40 solder is fairly forgiving. It flows smoothly, making it easier to create clean and reliable solder joints. Although, no one is born soldering perfectly; practice makes perfect! So grab some scrap wires and start honing your skills.

It's also found in a wide range of consumer electronics. From your smartphone to your TV remote, chances are that 60/40 solder has played a part in keeping those devices humming. It's the unsung hero of modern technology!

But, there's a bit of a debate now as some regions are moving away from lead-based solders due to environmental concerns. However, 60/40 solder still reigns supreme in many hobbyist and repair applications, mainly due to its excellent performance.

Beyond Electronics

3. Model Railroading and Hobby Projects

Believe it or not, 60/40 solder isn't just for electronic circuits. Model railroad enthusiasts often use it to join track sections and create intricate wiring systems for their miniature locomotives. The lower melting point makes it easy to work with delicate track components without causing damage.

Also, in the world of scale modeling, where precision is key, 60/40 solder provides a strong, reliable bond for assembling metal parts. Think about constructing a tiny, detailed airplane model — you need solder that can handle the intricate work without melting the plastic components.

Arts and crafts enthusiasts also occasionally find uses for 60/40 solder. Creating custom jewelry or repairing metal trinkets can benefit from its easy-to-use nature. Remember, ventilation is key when working with solder, so make sure you're in a well-ventilated area!

And lets not forget stained glass projects! 60/40 solder is a staple in that craft, ensuring those beautiful glass pieces stay together for years to come. It truly is a versatile material with a wide range of applications.

Safety First! Handling 60/40 Solder Responsibly

4. Ventilation, Ventilation, Ventilation!

Let's get one thing straight: soldering fumes aren't exactly the freshest mountain air. When you heat up solder, it releases fumes that can be harmful if inhaled in large quantities. That's why good ventilation is absolutely crucial. Open a window, use a fume extractor, or work outside — anything to keep those fumes away from your lungs.

Lead content is also a concern. Although 60/40 solder is widely used, lead is a toxic metal that can cause health problems if ingested or absorbed through the skin. Wash your hands thoroughly after handling solder, and avoid eating or drinking while you're working with it. Think of it like this: solder is for soldering, not for snacking!

Also, don't forget about eye protection! Splattering solder can happen, and you definitely don't want molten metal in your eyes. Wear safety glasses or goggles to protect your peepers from any accidental splashes. Your eyes will thank you.

Finally, be mindful of where you dispose of your solder scraps. Don't just toss them in the trash — recycle them responsibly. Many electronics recycling centers will accept solder scraps and ensure they're properly processed. A little environmental responsibility goes a long way.

Alternatives to 60/40 Solder

5. Lead-Free Options

As environmental awareness grows, lead-free solders are becoming increasingly popular. These alternatives typically use tin combined with other metals like silver, copper, or bismuth. While they might have slightly different melting points and flow characteristics, they offer a safer, more eco-friendly option.

Keep in mind that lead-free solders often require higher soldering temperatures. So, if you're switching from 60/40 solder, you might need to adjust your soldering iron's temperature setting. Don't just crank it up to eleven and hope for the best — experiment to find the sweet spot.

Another option is silver solder, which is often used for high-strength applications. Silver solder has a higher melting point than 60/40 solder, and it's more resistant to corrosion. Think of it as the bodybuilder of the soldering world — strong and durable.

For those who want to avoid the extra heat but have a good alternative, look at bismuth-based solders, these generally have lower melting points, and are a good mid-ground. Each type of solder has its own unique properties, so it's worth exploring different options to find what works best for your specific project.

What Is 60 40 Solder Homey Gears

FAQ

6. Quick Answers to Common Queries

Q: Is 60/40 solder safe to use?A: When used with proper safety precautions, such as adequate ventilation and handwashing, 60/40 solder can be safely used for various applications. However, keep in mind that it contains lead, so handle it responsibly and avoid ingestion or prolonged skin contact.

Q: Can I use 60/40 solder for plumbing?A: No, absolutely not! 60/40 solder is not designed for plumbing applications. Plumbing solder is specifically formulated to be safe for potable water systems, whereas 60/40 solder contains lead, which can contaminate drinking water. Stick to plumbing-specific solder for plumbing projects.

Q: What's the best temperature for soldering with 60/40 solder?A: A good starting point is around 370F (188C) for 60/40 solder. However, you may need to adjust the temperature depending on the size and type of components you're soldering. Experiment to find what works best for your specific setup. A stable temperature helps ensure you don't overheat and damage the components.