Looking Good Info About What Is The Problem Of Closed-loop System

What Is A Closed Loop Control System? ElectronicsHacks

Understanding the Hiccups in Closed-Loop Systems

1. The Promise and the Pitfalls

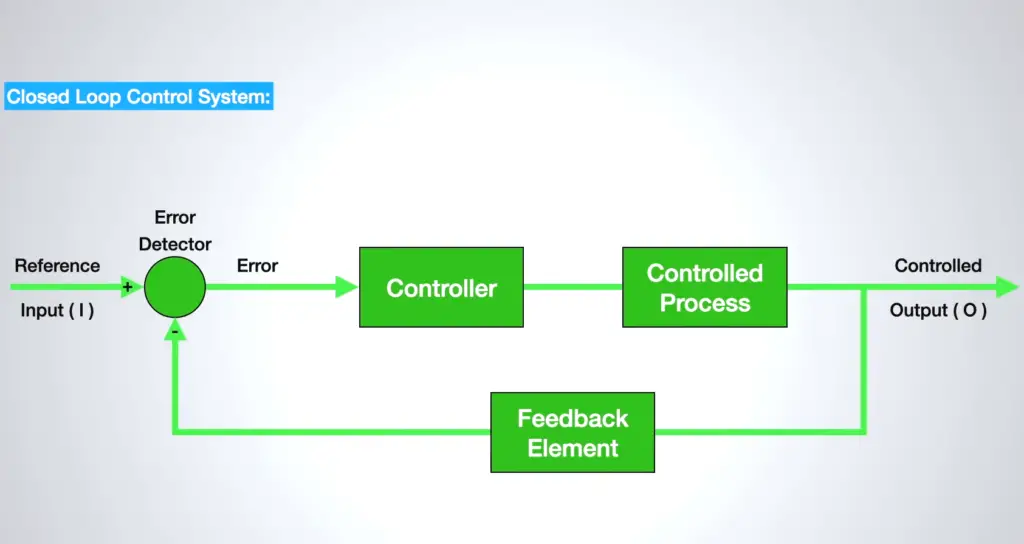

Closed-loop systems, also known as feedback control systems, are the workhorses of automation. Imagine your home thermostat — it constantly monitors the temperature and adjusts the heating or cooling to keep you comfy. That's a closed-loop system in action! These systems are designed to maintain a desired output by continuously comparing it to the actual output and making corrections. Sounds foolproof, right? Well, not always. While incredibly useful, these systems aren't immune to problems.

Think of it like trying to bake the perfect cake. You have a recipe (your desired output) and you keep checking the cake's progress (monitoring the actual output). If it's browning too fast, you lower the oven temperature (making a correction). But what if your oven temperature gauge is a bit wonky? Or what if you keep opening the oven door to check, causing the temperature to fluctuate wildly? Suddenly, that perfect cake seems a lot less likely. That's the essence of the challenges lurking within closed-loop systems.

The goal of a closed-loop system is stability, accuracy, and responsiveness. Its supposed to quickly and efficiently correct any deviations from the setpoint. However, achieving this ideal state can be surprisingly tricky. Several factors can throw a wrench in the works, leading to instability, sluggish performance, or even system failure. Let's delve into some of the common culprits that can turn a smooth-running closed-loop system into a chaotic mess.

So, what are these gremlins that plague our seemingly perfect systems? We'll explore some of the most common issues and understand why, despite their clever design, closed-loop systems can sometimes cause more headaches than solutions. From sensor inaccuracies to communication delays, we will examine these challenges and explore potential remedies.

Common Culprits Behind Closed-Loop System Problems

2. Digging into the Root Causes

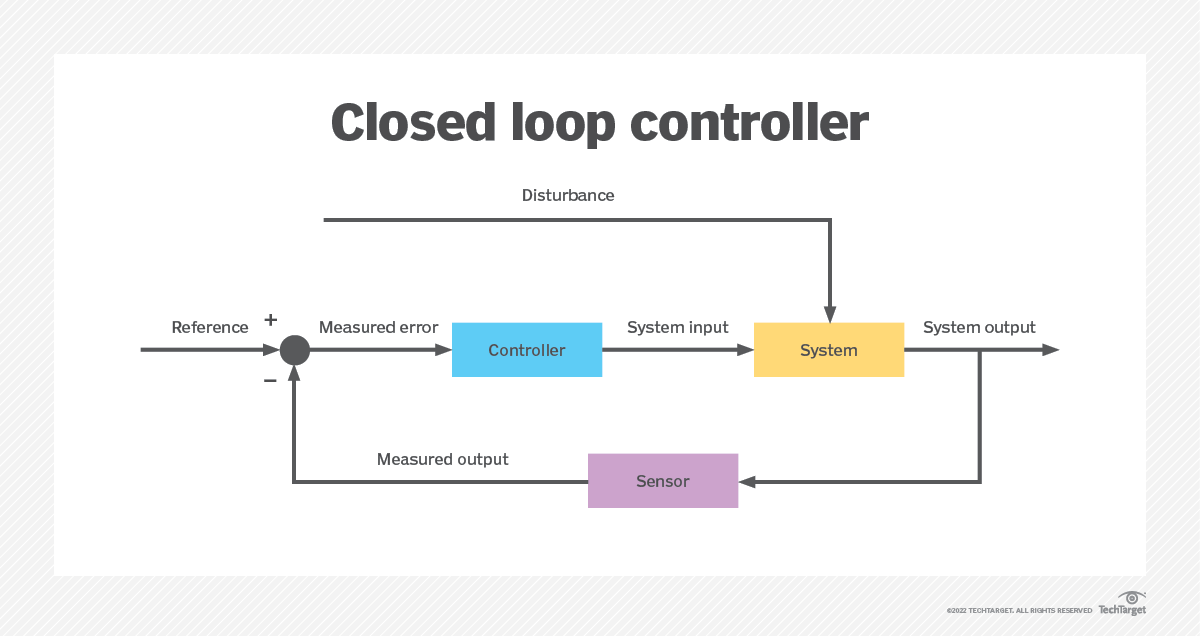

One of the biggest problems is instability. This happens when the system overcorrects, leading to oscillations or even runaway behavior. Imagine a self-driving car constantly swerving back and forth, trying to stay in its lane. That's instability in action. This often stems from high gain (amplification) in the feedback loop. A high gain means the system reacts very strongly to even small errors, potentially causing it to overshoot the target and then overcorrect in the opposite direction, leading to continuous oscillations.

Another common issue is time delay. This occurs when there's a delay between the system sensing the output and making a correction. Think of it as trying to steer a boat with a significant lag time. By the time you react to the current position, the boat has already moved further off course. In closed-loop systems, time delays can be caused by slow sensors, communication delays, or slow actuators. These delays can disrupt the feedback loop and lead to instability or poor performance.

Sensor inaccuracies are another major source of problems. If the sensors providing feedback are inaccurate, the system will be making corrections based on faulty information. This is like trying to bake a cake with a broken thermometer. You might think the oven is at the right temperature, but it's actually much hotter or colder, leading to a burnt or undercooked cake. Sensor noise, calibration errors, and environmental factors can all contribute to sensor inaccuracies. Choosing the right sensor for the application and regularly calibrating it are crucial for avoiding these issues.

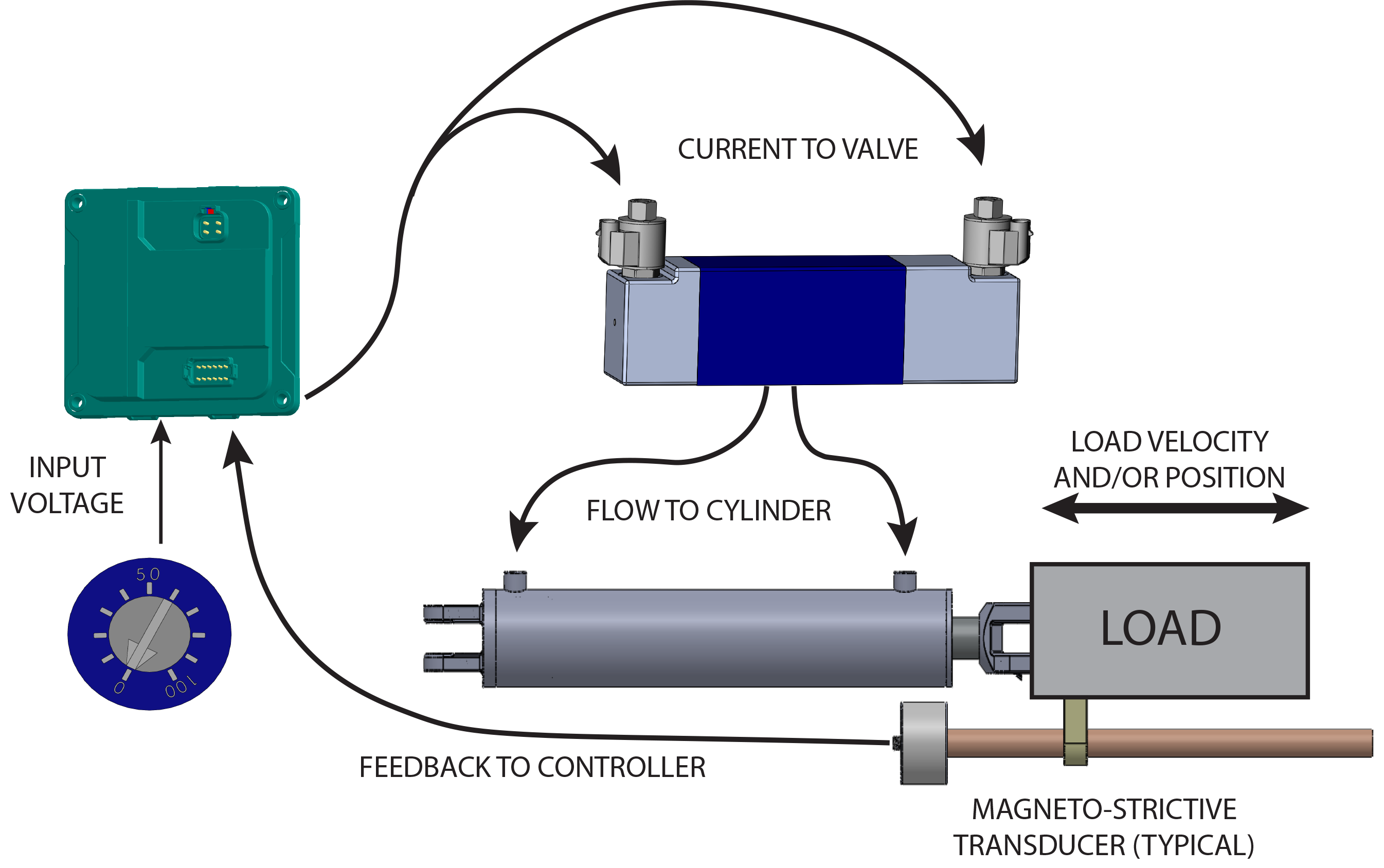

Then there's the problem of non-linearities. Many real-world systems exhibit non-linear behavior, meaning the relationship between the input and output isn't a straight line. This can make it difficult to design a controller that works well across the entire operating range. Think of a valve that is easy to open slightly, but becomes very difficult to open further. These non-linearities can cause unexpected behavior and make it harder to predict how the system will respond to changes.

Solved A Block Diagram Of Closedloop Control System In

The Feedback Fiasco

3. Unraveling the Unexpected Consequences

Sometimes, the very act of adding feedback can create problems. While feedback is designed to improve performance, it can also introduce new complexities and potential failure points. For instance, adding too much feedback can make the system overly sensitive to noise or disturbances. This is like turning up the volume on a microphone too high — it amplifies not only the signal but also all the background noise.

Another issue arises when the controller isn't properly tuned to the system. The controller is the brain of the closed-loop system, responsible for calculating the necessary corrections. If the controller parameters are not carefully chosen, the system may become unstable or exhibit poor performance. Tuning a controller is often an iterative process that involves experimentation and analysis to find the optimal settings.

Consider a system where the actuator (the device that makes the corrections) has limitations. For example, an actuator may have a limited range of motion or a maximum speed. These limitations can prevent the system from fully correcting errors, leading to degraded performance. It's like trying to steer a car with a broken steering wheel — you might be able to turn it a little, but not enough to avoid an obstacle.

Furthermore, unexpected interactions between different parts of the system can also cause problems. In complex systems with multiple interacting components, changes in one part of the system can have unforeseen effects on other parts. These interactions can be difficult to predict and can lead to instability or performance degradation. Thorough testing and simulation are essential for identifying and mitigating these potential problems.

Tuning Troubles

4. The Art and Science of Controller Adjustment

Controller tuning is arguably one of the most crucial aspects of implementing a successful closed-loop system, and also one of the most challenging. It's the process of adjusting the parameters of the controller to achieve the desired performance characteristics, such as stability, responsiveness, and accuracy. A poorly tuned controller can lead to oscillations, sluggish response, or even system instability. It's like trying to play a musical instrument that's out of tune — the notes just don't sound right.

There are various methods for controller tuning, ranging from manual trial-and-error to sophisticated automated techniques. Manual tuning typically involves adjusting the controller parameters (such as gain, integral time, and derivative time) based on observations of the system's response to disturbances. This can be a time-consuming and iterative process, requiring a good understanding of the system dynamics. Automated tuning methods use algorithms to automatically adjust the controller parameters based on measurements of the system's performance. These methods can be faster and more accurate than manual tuning, but they often require specialized software and expertise.

The optimal controller settings depend on the specific characteristics of the system being controlled. Factors such as the system's dynamics, time delays, and non-linearities can all influence the choice of controller parameters. It's important to consider these factors when tuning the controller and to use appropriate tuning methods for the application.

Keep in mind that good control is a balance. Overly aggressive tuning might result in quick response, but at the expense of stability. Gentle tuning might ensure stability but lead to sluggishness. Find the sweet spot and your closed-loop system will sing.

Closed Loop System Vs Open ChristinakruwMacias

Mitigating the Mess

5. Turning Problems into Solutions

Fortunately, there are several strategies you can employ to minimize the problems associated with closed-loop systems. First and foremost, careful design is essential. This includes selecting appropriate sensors, actuators, and controllers, and designing the system architecture to minimize time delays and non-linearities. A well-designed system is inherently more robust and less prone to problems.

Thorough testing and simulation are also crucial. Before deploying a closed-loop system in the real world, it's important to test it extensively under various operating conditions. Simulation can be used to model the system's behavior and identify potential problems before they occur. This can save time, money, and headaches in the long run.

Regular maintenance and calibration are also important for ensuring the long-term performance of closed-loop systems. Sensors should be calibrated regularly to ensure accuracy, and actuators should be inspected for wear and tear. Regular maintenance can prevent small problems from escalating into larger issues.

Dont underestimate the power of adaptive control. Adaptive control is a technique that allows the controller to automatically adjust its parameters in response to changes in the system or environment. This can be particularly useful for systems that operate under varying conditions or that exhibit time-varying dynamics. By adapting to changing conditions, adaptive control can maintain optimal performance even in the face of uncertainty.

Test Your Skills Opening Up About Closed Loop Control Fluid Power

Frequently Asked Questions (FAQs)

6. Answering Your Burning Questions

Q: Why use a closed-loop system at all if they have so many potential problems?

A: Despite the challenges, closed-loop systems offer superior accuracy and stability compared to open-loop systems. They automatically correct for disturbances and maintain the desired output, making them essential for many applications. The key is to understand the potential problems and take steps to mitigate them.

Q: How do I know if my closed-loop system is unstable?

A: Signs of instability include oscillations, overshooting, and runaway behavior. The system may constantly fluctuate around the setpoint or even diverge from it completely. If you observe these symptoms, it's a sign that the controller needs to be retuned or that there may be other problems with the system.

Q: What's the best way to tune a controller for a closed-loop system?

A: The best tuning method depends on the specific system and your available resources. Manual tuning can be effective for simple systems, while automated tuning methods are more suitable for complex systems. Start with a basic tuning method and refine your approach as needed.